Why d₃₃ is the Standard Benchmark in Piezoelectric Studies (and Not d₃₁)

If you open any datasheet of a piezoelectric ceramic or read a research article on new piezoelectric materials, one number almost always stands out: the d33 value. This coefficient is known as piezoelectric coefficient (dij) and is treated as the performance benchmark for piezoelectrics, while its companion, d31, is rarely emphasized. For students, this raises a common question: why is d33 so important, and why doesn’t d31 get the same attention?

To answer this, we need to understand not only what these coefficients mean, but also how they are measured, why their magnitudes differ, and how they are used in real-world devices.

Table of Contents

What Do d₃₃ and d₃₁ Mean?

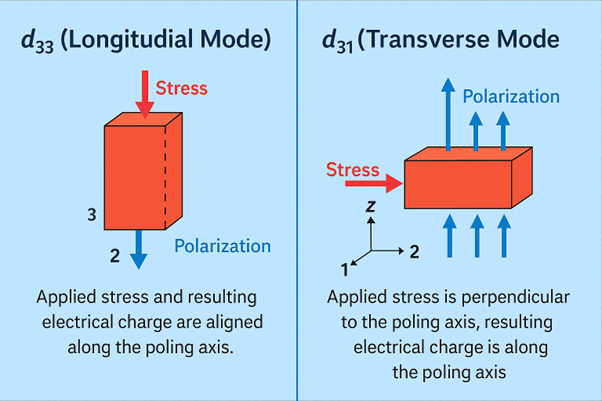

The piezoelectric coefficient (dij) describes the relationship between the applied stress (force per unit area) and the generated electrical charge (Polarization). Here, the first subscript ‘i’ indicates the direction of polarization (charge displacement), and the second subscript ‘j’ indicates the direction of applied stress or strain.

Longitudinal mode(d33)

- In d33 (longitudinal mode), the applied mechanical stress and the resulting electrical charge are both aligned along the poling axis of the material, designated as the “3” direction. This mode is called longitudinal because the force and the electrical response occur in the same axis, parallel to the direction in which the material was originally poled. A simple way to visualize this is by pressing a piezoelectric block from the top, applying stress vertically along its poling direction. In response, the block generates electrical charge that is also oriented vertically, following the same axis as the applied stress. Because the mechanical and electrical effects reinforce each other along the same path, d33 typically produces the strongest response among piezoelectric coefficients. For this reason, it is widely used in devices like sensors, actuators, and ultrasonic transducers, where maximizing the conversion of mechanical energy to electrical energy (or vice versa) is crucial.

Longitudinal mode(d31)

- In d31 (transverse mode), the applied stress is directed perpendicular to the poling axis, while the resulting electrical charge is still collected along the poling direction, labelled as the “3” axis. This mode is called transverse because the mechanical force and the electrical response occur orthogonally. To visualize this, imagine a piezoelectric plate that has been poled vertically. If you apply a compressive or tensile force sideways, along the horizontal axis (the “1” direction), the material will still generate charge along the vertical poling axis (the “3” direction) but in lesser quantity. Unlike the longitudinal mode, where stress and charge act in the same direction, the transverse mode couples perpendicular stress with vertical polarization. Because of this geometry, d31 values are generally smaller in magnitude and often negative compared to d33. However, despite being weaker, the transverse effect is extremely important in applications such as MEMS devices, cantilevers, thin films, and energy harvesters, where in-plane stresses dominate the operation of the device.

Why d₃₃ Became the Benchmark?

Several scientific and practical reasons explain the dominance of d33.

- Ease of Measurement

The most widely used method, the Berlincourt piezometer, directly measures d33 by applying a small oscillating force along the poling axis. This test is simple, fast, and standardized. Measuring d31, on the other hand, requires complex indirect methods such as resonance analysis or interferometry, making it less convenient. - Stronger Response

Because piezoelectric materials are poled along the “3” axis, the response in this direction is naturally the strongest. In typical ceramics like PZT, d33 values range between 300–600 pC/N, while d31 values are smaller and often negative (around –100 to –250 pC/N). A larger number not only looks impressive but also reflects better energy conversion efficiency. - Universal Standardization

Over time, d33 became the common language of the piezoelectric community. Since almost every group reports it, d33 enables researchers and engineers worldwide to compare results reliably. - Direct Relevance to Devices

Many key applications — ultrasonic transducers, actuators, and sensors — rely primarily on longitudinal effects. Reporting d33 directly connects to how the material will behave in these devices.

Where d₃₁ Really Matters?

- Although d33 takes the spotlight, d31 is not irrelevant. In fact, in some devices it plays a decisive role. In devices where the mechanical stress is applied sideways (in-plane) rather than along the poling axis, the transverse piezoelectric coefficient d31 becomes dominant.

- Bending Devices (Cantilevers, Bimorphs):

When a cantilever beam bends, the top surface undergoes compression and the bottom surface experiences tension. This stress is perpendicular to the poling axis (i.e., along the “1” direction). The electrical response is still measured along the poling axis (“3”), so d31 governs the output. - Thin Films:

In thin piezoelectric films deposited on rigid substrates (like silicon wafers in MEMS), the vertical movement is clamped and cannot respond freely. As a result, the stress is mostly in-plane, making d31 the key parameter.

- In-Plane Stress Devices (SAW, RF Filters):

Surface acoustic waves (SAW) generate strain along the surface of the material. Since these are in-plane stresses, the coupling is described by d31. - ✅ Rule of Thumb:

Whenever a device bends or operates in thin-film form, the response you care about comes from d31, not d33.

Final Thoughts

The reason d33 is the standard benchmark in piezoelectric studies comes down to three things: it is easier to measure, it shows a larger and stronger response, and it has become a globally accepted reference for comparing materials. However, for a complete picture, scholars must remember that d31 is not secondary in importance — it is simply less convenient to measure and less often reported. In certain devices, d31 is not just relevant but critical to performance.

So, while d33 serves as the headline figure, the real story of piezoelectricity is incomplete without understanding both d33 and d31.

Both coefficients are equally valid, measurable, and significant. However, their practical importance is determined by the device architecture, with the relevant value measured accordingly.

| Parameter | d33 (Longitudinal) | d31 (Transverse) |

|---|---|---|

| Stress direction | Along poling axis | Perpendicular to poling axis |

| Charge direction | Along poling axis | Along poling axis |

| Typical magnitude | 300–600 pC/N | −100 to −250 pC/N |

| Measurement | Easy (Berlincourt method) | Complex (resonance analysis, interferometry) |

| Applications | Sensors, actuators, ultrasonic transducers | Cantilevers, MEMS thin films, SAW / RF filters |

Frequently Asked Questions (Piezoelectric d33 vs d31)

The constants d₃₃ and d₃₁ describe piezoelectric strain responses under applied electric fields.

- d₃₃ (longitudinal mode): strain and electric field are applied in the same direction.

- d₃₁ (transverse mode): strain response is measured perpendicular to the applied field direction.

d₃₃ provides higher and more direct piezoelectric response values, simpler measurement setups, and greater reproducibility across materials and laboratories. It strongly correlates with performance in sensors, actuators, and energy-harvesting devices.

Applications such as precision actuators, ultrasonic transducers, MEMS resonators, energy harvesters, and medical imaging devices depend heavily on d₃₃ due to high displacement and sensitivity in the direction of the electric field.

Yes. d₃₁ is crucial in bending-mode devices like cantilevers, bimorph actuators, flexible sensors, and structural health monitoring systems, where bending response is required.

d₃₃ measurement involves direct displacement or charge sensing with minimal mechanical constraints, whereas d₃₁ requires complex mounting and controlled stress, increasing measurement uncertainty.

No. True performance also depends on dielectric loss, Qm, Curie temperature, coercive field, fatigue stability, and domain mobility besides d₃₃ magnitude.

Poling aligns ferroelectric domains to enhance strain response. d₃₃ aligns with the poling axis and is stronger, while d₃₁ involves perpendicular deformation, giving lower response.

References

- Jaffe, B., Cook, W. R., & Jaffe, H. (1971). Piezoelectric ceramics. Academic Press.

- Berlincourt, D. A. (1971). Piezoelectric crystals and ceramics. Proceedings of the IEEE, 55(6), 782–802. https://doi.org/10.1109/PROC.1971.8285

- Safari, A., & Akdogan, E. K. (2008). Piezoelectric and acoustic materials for transducer applications. Springer.

- IEEE Standards Board. (1987). IEEE standard on piezoelectricity (ANSI/IEEE Std 176-1987). Institute of Electrical and Electronics Engineers.

- Damjanovic, D. (1998). Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Reports on Progress in Physics, 61(9), 1267–1324. https://doi.org/10.1088/0034-4885/61/9/002

- Uchino, K. (2017). Ferroelectric devices. CRC Press.

Dr. Rolly Verma

If you notice any inaccuracies or have constructive suggestions to improve the content, I warmly welcome your feedback. It helps maintain the quality and clarity of this educational resource. You can reach me at: advancematerialslab27@gmail.com